In today’s rapidly evolving digital landscape, digital twins are emerging as a transformative technology with the potential to revolutionize industries. A digital twin is a virtual representation of a physical asset, process, or system, enabling businesses to gain valuable insights, optimize operations, and drive innovation. This article explores the concept of digital twins, delving into their core components, functionalities, and diverse business applications. Understanding the potential of digital twins is crucial for businesses seeking to enhance their competitive advantage in the digital age.

From manufacturing and healthcare to energy and urban planning, digital twins are finding business applications across a wide range of sectors. By creating a dynamic virtual replica, organizations can simulate real-world scenarios, analyze performance data, and predict future outcomes. This empowers businesses to make data-driven decisions, improve efficiency, reduce risks, and accelerate product development. This article will examine the key business applications of digital twins, illustrating how they are transforming industries and driving significant business value. We will explore the practical implementations and benefits of leveraging digital twins to optimize processes, improve product design, and enhance customer experiences.

What is a Digital Twin?

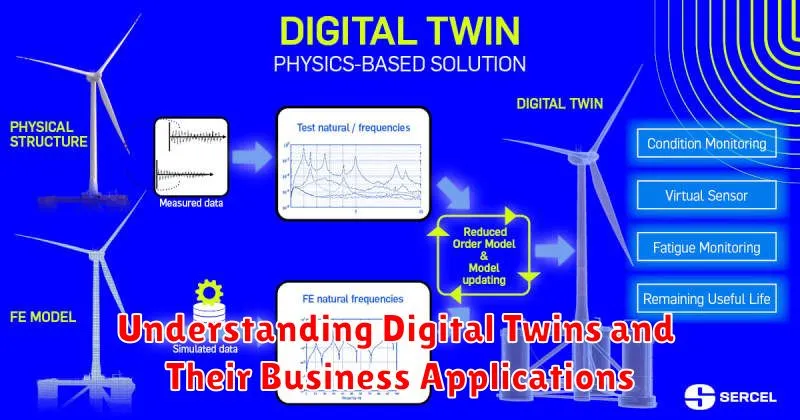

A digital twin is a virtual representation of a physical object, process, or system. This virtual model can be as simple as a 3D rendering of a product or as complex as a dynamic simulation of a manufacturing plant. It uses real-time data and other information to mirror the behavior and performance of its physical counterpart.

Key characteristics of a digital twin include being data-driven, dynamic, and interactive. The connection to the physical twin allows for continuous monitoring, analysis, and optimization. This can lead to improved decision-making and better outcomes in various applications.

Industries Benefiting from Digital Twins

Digital twin technology offers transformative potential across diverse sectors. Manufacturing benefits from optimized production processes, predictive maintenance, and improved product design. The healthcare industry leverages digital twins for personalized medicine, drug discovery, and surgical planning.

Smart cities utilize digital twins to model and manage infrastructure, optimize traffic flow, and enhance public safety. In the energy sector, digital twins optimize energy production, distribution, and consumption, contributing to greater efficiency and sustainability.

Other notable industries experiencing the positive impact of digital twins include aerospace, automotive, and construction, where improved designs, streamlined operations, and enhanced safety are key advantages.

Improving Product Development and Testing

Digital twins offer significant advantages in product development and testing. By creating a virtual representation of a product, organizations can simulate its performance under various conditions without the need for physical prototypes. This reduces development time and costs.

Testing becomes more efficient and comprehensive with digital twins. Engineers can simulate real-world scenarios, including extreme conditions and failure points, to identify potential issues early in the design process. This proactive approach leads to improved product quality and reliability.

Furthermore, digital twins allow for iterative design improvements. By analyzing simulation data, engineers can quickly identify areas for optimization and implement changes in the virtual model before applying them to the physical product. This agile approach fosters innovation and ensures the final product meets performance expectations.

Enhanced Asset Management

Digital twins offer significant advancements in asset management. By creating a virtual representation of a physical asset, organizations gain real-time insights into its performance, condition, and lifecycle.

This allows for predictive maintenance, reducing downtime and optimizing maintenance schedules. Potential issues can be identified and addressed before they escalate into costly problems.

Furthermore, digital twins enable better decision-making regarding asset utilization, resource allocation, and future investments. Analyzing data from the digital twin helps organizations understand how to improve asset efficiency and extend their operational lifespan.

Predictive Maintenance Applications

Predictive maintenance leverages digital twins to forecast equipment failures before they occur. By analyzing real-time data from the twin, businesses can identify potential issues and schedule maintenance proactively. This minimizes downtime, optimizes maintenance schedules, and extends the lifespan of critical assets.

For example, in manufacturing, a digital twin of a production line can predict when a specific component, like a motor, is likely to fail. Maintenance can then be scheduled during planned downtime, preventing costly unplanned outages and production losses.

Implementing Digital Twin Technology

Implementing a digital twin involves several key steps. It begins with defining the objectives and scope of the digital twin. What specific aspects of the physical asset or process are you trying to model and analyze?

Next, data acquisition is crucial. Sensors and other data sources are used to collect real-time information from the physical counterpart. This data feeds the digital twin, enabling it to mirror the real-world behavior.

Building the digital model involves using specialized software and expertise. This model represents the physical asset or process virtually, incorporating its geometry, physics, and behavior.

Finally, validation and calibration are essential. The digital twin must accurately reflect the real-world system. This requires continuous monitoring and adjustment to ensure its effectiveness.

Costs and Resources Required

Implementing digital twins requires a significant investment. Costs vary widely depending on the complexity of the twin, the industry, and the specific application. Key cost drivers include software and hardware, data acquisition and processing, development and integration, and ongoing maintenance and support.

Resource allocation is another critical aspect. Successful digital twin projects demand skilled personnel with expertise in areas such as data science, software engineering, and domain-specific knowledge. Furthermore, robust IT infrastructure and efficient data management processes are essential for handling the large volumes of data generated and used by digital twins.

Security and Data Management Concerns

As digital twins involve the collection and analysis of substantial amounts of sensitive data, security is a critical concern. Protecting these digital representations from unauthorized access, modification, and breaches is paramount. Robust cybersecurity measures are essential to maintain the integrity and trustworthiness of the digital twin and the physical asset it represents.

Effective data management is also crucial. The sheer volume of data generated by digital twins requires careful planning and implementation of data storage, processing, and analysis strategies. This includes addressing data quality, consistency, and accessibility to ensure the digital twin remains a reliable and valuable tool.

Successful Digital Twin Case Studies

Examining real-world implementations provides a clearer understanding of the power of digital twins. Here are a few brief examples:

Manufacturing

A leading automotive manufacturer utilized a digital twin of their production line to optimize robot placement and improve overall efficiency, resulting in a significant reduction in production time.

Healthcare

Digital twins of human organs are enabling medical professionals to simulate surgical procedures and personalize treatment plans, leading to improved patient outcomes.

City Planning

Urban planners are leveraging digital twins of cities to model traffic flow and plan infrastructure improvements, optimizing resource allocation and citizen well-being.

Future Prospects and Innovations

The field of digital twins is rapidly evolving, promising exciting advancements across various sectors. Real-time data integration and advanced analytics will drive more accurate and responsive digital twins. This enhanced fidelity will unlock new possibilities for predictive maintenance, optimization, and design.

Artificial intelligence (AI) and machine learning (ML) are poised to play a crucial role. AI-powered digital twins will be capable of autonomous decision-making, enabling self-optimizing systems and processes. Integration with emerging technologies like edge computing will further empower real-time insights and control.